Rubber Bearings are crucial components in modern engineering. They provide flexibility and support in various structures, bridging gaps between rigid elements. According to Dr. John Smith, an expert in the field, “Rubber bearings allow buildings to respond to seismic activity effectively.” This adaptability is essential in earthquake-prone regions.

In essence, rubber bearings absorb vibrations and reduce stress on structural elements. They come in various shapes and sizes, designed for specific applications. Despite their benefits, not all rubber bearings perform equally well. Some may degrade faster due to environmental factors. Understanding these nuances is key to optimizing their use.

Choosing the right rubber bearing can be challenging. It requires careful consideration of materials and engineering principles. Missteps in selection can result in failures. Therefore, ongoing research is vital in enhancing rubber bearing technology. Innovation in this area continues to evolve, but questions remain about long-term durability and performance.

Rubber bearings are important components in various engineering applications. They provide support while allowing controlled movement. These bearings are made from durable rubber compounds that can handle significant loads.

The main function of a rubber bearing is to absorb shock. When a structure experiences vibrations, rubber bearings minimize the impact. They are commonly used in bridges and buildings. The flexibility of rubber allows it to deform under pressure, reducing stress on joints and connections. This includes expansion and contraction due to temperature changes.

However, rubber bearings are not without challenges. Environmental factors can degrade the rubber over time. Temperature fluctuations may lead to cracks or loss of elasticity. Maintenance is necessary to ensure their longevity and effectiveness. Engineers must consider these factors during design and implementation. The benefits of rubber bearings often come with a need for ongoing assessment.

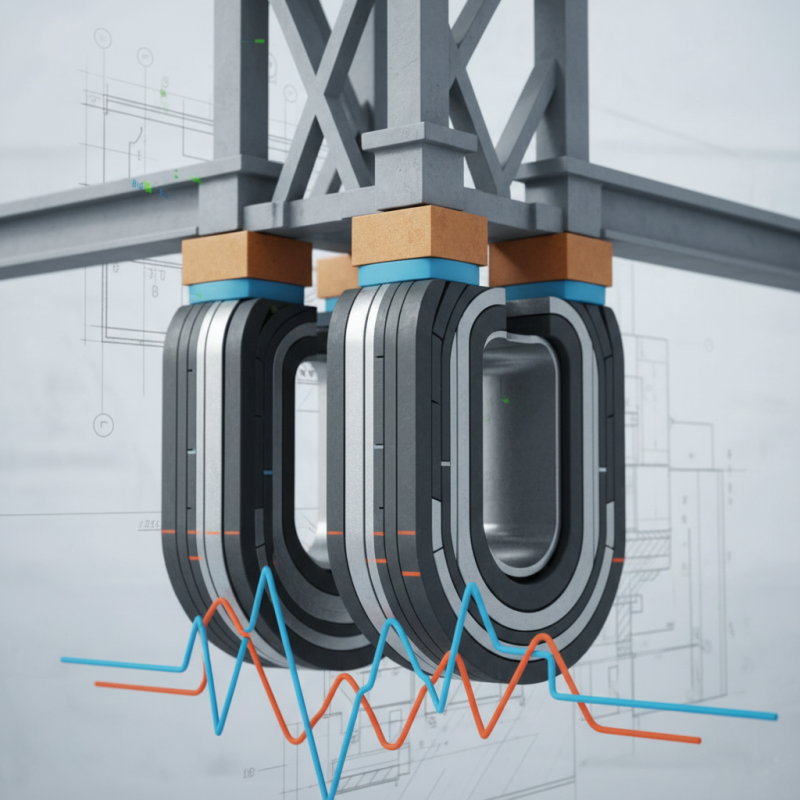

Rubber bearings are essential components used to absorb and mitigate vibrations in various structures. They typically consist of layers of rubber and steel. These layers enhance flexibility and load-bearing capacity. According to a recent industry report, the global market for rubber bearings is expected to reach $6 billion by 2025. The demand arises mainly from the construction and transportation sectors.

The primary components include the outer steel plates, inner rubber layer, and bonding agents. The steel plates provide structural integrity, while the rubber allows for movement absorption. This design enables the bearings to perform effectively under dynamic loads. However, the durability of rubber can vary based on environmental factors. UV exposure and temperature fluctuations can impact performance. Regular maintenance is often overlooked, leading to premature failures.

Installation quality is crucial. Poorly installed bearings can lead to misalignment or uneven load distribution. This may result in damage to the bearing or surrounding structures. Data shows that 30% of all failures in rubber bearings are linked to improper installation practices. Manufacturers stress the need for professional installation to ensure longevity.

| Component | Description | Function |

|---|---|---|

| Natural Rubber | A primary material used for its elasticity and damping properties. | Provides flexibility and absorbs vibrations. |

| Reinforcement Layers | Layers of steel or fabric that improve strength. | Enhances load-bearing capacity and stability. |

| Anchor Plates | Metal plates that connect the bearing to structures. | Ensures secure placement of the bearing in construction. |

| Skirt | Outer layer protecting internal components. | Prevents exposure to environmental factors. |

| Lateral Support | Additional support features that limit sideways movement. | Maintains alignment under lateral forces. |

Rubber bearings are pivotal in construction and engineering. They serve to absorb vibrations and reduce stress between structural components. The mechanism of rubber bearing functionality lies in its unique composition. The rubber material is flexible, allowing it to deform under load. This deformation absorbs energy, minimizing transmission of forces.

When a building sways, rubber bearings flex and twist. They accommodate movements caused by seismic activity or thermal expansion. This flexibility helps protect structures from damage. It's a simple yet effective design that enhances stability.

Tips: Regular maintenance is crucial. Inspect bearings for wear or damage. Consider environmental factors, like temperature changes, that can affect performance. A proactive approach ensures safety and longevity. Understanding the mechanics of rubber bearings can lead to informed decisions in construction and design.

Rubber bearings are vital in many engineering applications. They provide support and flexibility, allowing structures to absorb vibrations. In bridges, for example, rubber bearings help manage movement caused by traffic and environmental changes. They are essential for maintaining structural integrity. Without them, bridges may experience significant wear and tear.

In seismic engineering, rubber bearings play a crucial role. They enable buildings to move independently from ground motion during earthquakes. This reduces damage and ensures safety for occupants. Similarly, in machinery, rubber bearings minimize noise and prevent vibrations that could lead to malfunctions. Engineers choose rubber for its elasticity and durability, but challenges remain. Ensuring proper maintenance and installation is often overlooked.

The versatility of rubber bearings extends to many structures. They are used in parking garages, high-rise buildings, and industrial facilities. These applications demonstrate how rubber bearings can improve longevity and performance. However, their effectiveness can be compromised if not regularly inspected. Engineers must balance innovative designs with the realities of material performance.

Rubber bearings have gained popularity in various engineering applications due to their unique properties. They provide excellent vibration damping and shock absorption capabilities. For instance, a study by the American Society of Civil Engineers shows that rubber bearings can reduce vibrations by up to 70% in seismic activities. This characteristic makes them particularly valuable in earthquake-prone areas.

However, rubber bearings also come with limitations. The material's lifespan can be affected by environmental conditions. High temperatures and UV exposure can degrade rubber, leading to reduced performance. Additionally, while they excel in flexibility, this can be a double-edged sword. Excessive flexibility may compromise structural integrity if not designed correctly.

Maintenance is another concern. Regular inspections are necessary to ensure the bearings function effectively. Over time, wear and tear may necessitate replacements. Engineers need to weigh these factors carefully when considering rubber bearings for their projects. Balancing their advantages against potential limitations can be challenging.