The use of a laser cutting machine has revolutionized various industries, offering precision and efficiency. According to a report by IBISWorld, the laser cutting industry is expected to grow by 5% annually. This growth highlights the increasing demand for high-quality cutting solutions.

laser cutting machines are known for their ability to create intricate designs with minimal waste. They can cut through materials like metal, wood, and plastic with ease. The American Society for Laser Applications states that laser cutting enhances production speed by 25%. This significant improvement draws many manufacturers to invest in cutting-edge technology.

However, transitioning to a laser cutting machine isn’t without challenges. Initial costs can be high, and technical training is necessary for staff. Companies need to weigh these factors carefully. Despite these hurdles, the benefits often outweigh the drawbacks, making laser cutting machines an integral part of modern manufacturing.

Laser cutting technology offers significant advantages across various industries. Its precision makes it ideal for intricate designs. According to a report by MarketsandMarkets, the global laser cutting market is expected to reach $5 billion by 2025. This suggests increased reliance on the technology for manufacturing processes.

One key benefit is the efficiency of laser cutting. This method reduces material waste significantly. A study by the International Journal of Advanced Manufacturing Technology highlighted that laser cutting can minimize waste by up to 25%. However, not all materials can be effectively cut using lasers. Some materials may melt or warp due to heat. Users must consider these limitations carefully.

Cost-effectiveness is another point to ponder. While initial investment may be high, long-term savings are considerable. Laser cutting machines often have lower operational costs than traditional methods. They require less maintenance and operate faster. Yet, the complexity in setting up the machine can lead to unforeseen downtime. This setup time is vital to address before beginning production.

Laser cutting machines are revolutionizing the way materials are processed. The precision they offer is unmatched. These machines can cut through various materials with incredible accuracy. Whether it's metal, wood, or fabric, the results are clean and detailed. This level of precision reduces waste and saves time.

When working with a laser cutter, attention to detail is crucial. Always double-check your designs before starting the cut. Small mistakes can lead to larger issues. Ensure that your materials are securely in place. This helps prevent any shifting during the cutting process.

Another important aspect is understanding your settings. Adjusting power and speed can significantly alter the outcome. Don't be afraid to run small test cuts first. A little experimentation can go a long way. It's essential to recognize that even with high precision, imperfections can occur. Reflecting on these challenges will improve your skills over time.

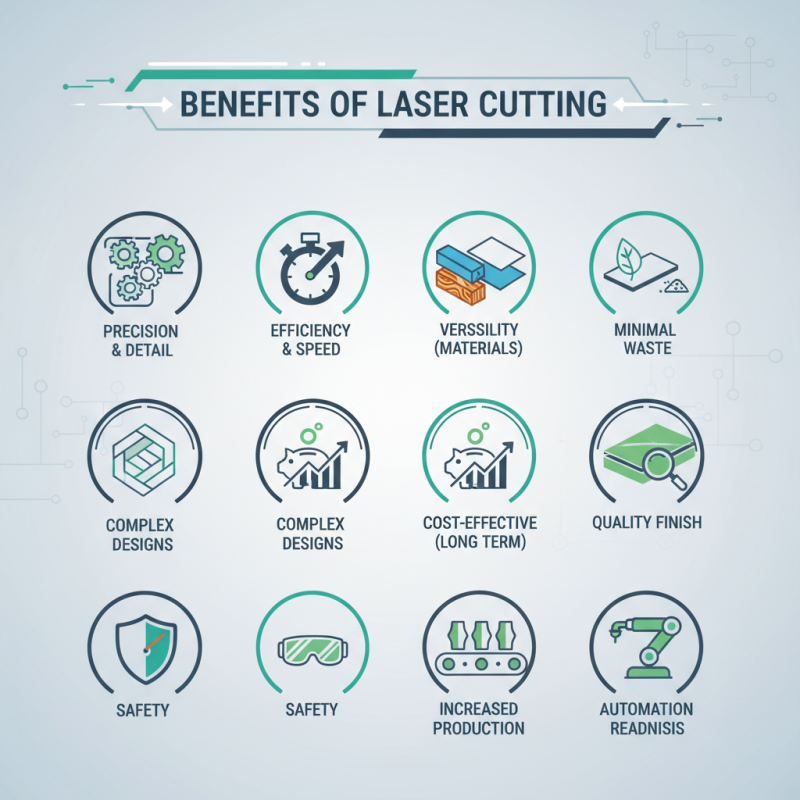

This chart illustrates the top 10 benefits of using a laser cutting machine, showcasing how each benefit scores on a scale of 1 to 10 based on importance and practicality in various applications.

Laser cutting machines offer incredible versatility for various materials and applications. They efficiently cut metals, plastics, wood, and fabrics. A recent industry report from SME reveals that laser cutting can improve production speed by up to 75%. This enhances workflow in manufacturing settings and reduces material waste, which is crucial in today's resource-conscious environment.

However, using laser cutting systems requires a learning curve. Operators need to understand settings like power and speed for different materials. For example, cutting acrylic can differ significantly from cutting stainless steel. Mishaps can lead to imperfect cuts and wasted materials. It's essential for teams to continually refine their techniques to maximize efficiency.

In addition to cutting, laser machines also allow engraving and marking. This adds value to products by providing branding solutions in the same process. However, the challenge lies in ensuring precision across diverse applications. Some operators may struggle with settings, leading to inconsistent results. Continuous training and adaptation are necessary for effective use across multiple projects.

| Benefit | Description | Material Compatibility | Applications |

|---|---|---|---|

| Precision Cutting | Laser cutting offers high precision with intricate design capabilities. | Metals, Wood, Acrylic | Custom designs, Art installations |

| Minimal Material Waste | Efficient cutting paths reduce scrap material. | Paper, Cardboard, Fabric | Packaging, Textiles |

| Versatility | Works across various materials and thicknesses. | Plastics, Leather, Glass | Fashion, Signage |

| Speed | Laser cutting can operate at high speeds, increasing productivity. | Metals, Wood | Industrial Applications |

| No Tool Wear | Lasers do not dull or wear out like traditional cutting tools. | All materials | Consistent Quality Production |

| Automation | Easily integrated into automated systems for continual operation. | All materials | Mass Production |

| Safe Operation | Laser cutting is generally safer with fewer physical hazards. | Metals, Plastics | Consumer Goods Manufacturing |

| High-Quality Finish | Laser cutting provides a clean and polished edge on materials. | Wood, Acrylic, Metals | Architectural Elements, Decorative Items |

| Custom Designs | Ideal for creating one-off custom designs and prototypes. | All materials | Prototyping, Artworks |

| Reduced Lead Times | Faster project turnaround compared to traditional methods. | Composites, Metals | Manufacturing, Workshops |

Laser cutting machines have revolutionized production processes, significantly enhancing efficiency and speed. According to a 2022 report by the Manufacturing Institute, companies using laser cutting technology have witnessed up to a 30% reduction in production time. This is primarily due to their precision and ability to handle complex designs. Traditional methods often struggle with intricate patterns, leading to longer turnaround times. In contrast, laser cutting ensures clean edges and minimizes material waste, which makes it a more strategic choice for many manufacturers.

Moreover, the speed at which laser cutting machines operate can lead to faster project completion. A study by the American Society for Precision Engineering found that laser cutting can outperform conventional techniques by as much as 50%. Companies benefit from this speed, allowing them to meet tight deadlines and adapt quickly to market demands. However, the initial investment in laser technology can be daunting, and not all businesses can readily make the switch. This reflects a crucial point that while the usage of laser cutting machines brings numerous advantages, the transition requires careful planning and consideration of long-term returns versus initial costs.

Laser cutting machines have transformed various industries, offering crucial cost-effectiveness for both small and large-scale projects. According to a 2022 report by IBISWorld, the laser cutting industry is valued at over $5 billion and continues to grow at a steady pace. This growth indicates a demand for precision and efficiency across multiple sectors such as manufacturing, automotive, and aerospace.

For small businesses, laser cutting machines reduce material waste significantly. The high precision allows for intricate designs without sacrificing quality. Reports suggest that businesses save up to 30% on materials by using laser technology compared to traditional cutting methods. Small batches can be produced cost-effectively, enabling artisans and startups to compete with larger firms. Yet, the initial investment can be daunting for some. It's essential for smaller players to assess their production needs carefully.

On the other hand, large manufacturers benefit from scalability. The ability to automate processes increases output without a proportional increase in labor costs. A study by Market Research Future notes that large companies can improve production speed by up to 50% through the integration of laser cutting technologies. However, high maintenance costs and the need for skilled operators can become potential drawbacks. Balancing these aspects requires careful planning and ongoing assessment.

Laser cutting machines offer numerous advantages that make them an essential tool in modern manufacturing and design. One of the key benefits is their exceptional precision and accuracy, allowing for intricate designs and detailed cuts across various materials, from metals to plastics. This versatility enables industries to adapt laser cutting technology for diverse applications, enhancing production processes.

Moreover, laser cutting machines contribute significantly to efficiency and speed, reducing turnaround time for projects both large and small. They are also cost-effective, as they minimize labor and material expenses while producing high-quality results. Additionally, the technology reduces material waste, leading to a more sustainable approach to manufacturing and a lower environmental impact overall. Embracing laser cutting technology can therefore provide businesses with a competitive edge while promoting eco-friendly practices.